Bearing strength test and securing the required bearing capacity

HANCHANG

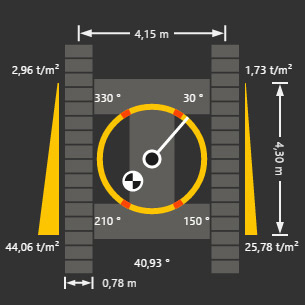

The ground load-bearing capacity and the monitoring of the ground pressure are decisive for the safe operation of a crane. Ground Pressure Visualization calculates the current ground pressure of the machine in real time and compares it with the specified safety limits that the operator has entered in the control system

The ground pressure is displayed on the monitor and the operator is permanently aware of whether the machine is in or approaching a critical area. Dangerous work steps can so be avoided or safely adapted in good time.

Ground reinforcement for crawler crane is essential work. If equipment is supplied without ground reinforcement, the ground is likely to fall. Such an accident occurs often. As for the weak ground, it is required to analyze the bearing force of soil first and to determined whether to be workable. If the bearing force is weak, it is required to plan ground reinforcement in order to secure enough bearing force before equipment is supplied and to make work safe.

Ground reinforcement for crawler crane is essential work. If equipment is supplied without ground reinforcement, the ground is likely to fall. Such an accident occurs often. As for the weak ground, it is required to analyze the bearing force of soil first and to determined whether to be workable. If the bearing force is weak, it is required to plan ground reinforcement in order to secure enough bearing force before equipment is supplied and to make work safe.