Preliminary inspection on the entire parts of crane with safety manager and repair technician in attendance before the supply of crane to a construction site

Measures taken completely if any unsuitable point is found, before the supply of equipment a construction site

Before supply, completion of non-destructive inspection on the crane boom whose specifications meet field conditions

| Inspection type | Inspection item | |

|---|---|---|

| Non-destructive inspection | 1) All of boom welding part | Magnetic Particle Test : Not performed |

| 2) All of the upper and lower welding parts of turn table | ||

| 3) Track driving part | ||

| 4) A-frame structure part | ||

| 5) Connection bolts of main structure part | Ultrasonic Test : Not performed | |

| 6) Fixture bolts for ring-gear connection | ||

| Naked eye, Punching, Measurement | 1) Structure part: External appearance inspection (twisting, bending, cracking) | |

| 2) Mechanical device ① Driving device: Whether the connected bolts are loosened, the status of each switch, etc. ② Sheave bearing and pin: Abrasion, cracks, etc. of sheave groove and arm & boss ③ Wire rope: Damage & cracks, fracture, corrosion, etc. ④ Inspection of cracks, abrasion, etc. of other devices |

||

| 3) Slewing device | ||

| 4) Electric device | ||

[Display of inspection result] O(OK), △(Adjustment & Supplement), X(NG), N/A(not applicable)

| Inspection item | Inspection point | Inspection content | Result | Non-conforming content |

|---|---|---|---|---|

| 1) Boom | ① External appearance | Twisting, bending, cracking, and transforming state | O | |

| Fracture, peeling and loss state | O | |||

| ② Welding part | Incomplete penetration, blow hole, undercut, overlap, and son on | O | ||

| Surface crack and internal penetration state | O | |||

| Corrosion and oxidation state | O | |||

| ③ Connection part | Crack, abrasion, and transformation state | O | ||

| Corrosion and loosening state | O | |||

| 2) Turntable structure part | ① External appearance part | Twisting, bending, cracking, and transforming state | O | |

| Fracture, peeling and loss state | O | |||

| ② Welding part | Incomplete penetration, blow hole, undercut, overlap, and son on | O | ||

| Surface crack and internal penetration state | O | |||

| Corrosion and oxidation state | O | |||

| 3) A-frame connection part (tower head) | ① External appearance part | Twisting, bending, cracking, and transforming state | O | |

| Fracture, peeling and loss state | O | |||

| ② Welding part | Incomplete penetration, blow hole, undercut, overlap, and son on | O | ||

| Surface crack and internal penetration state | O | |||

| Corrosion and oxidation state | O | |||

| 4) Connection pin & bolt | ① Structure and surface part | Twisting, bending, cracking, and transforming state | O | |

| Internal and external crack state | O |

[Display of inspection result] O(OK), △(Adjustment & Supplement), X(NG), N/A(not applicable)

| Inspection item | Inspection content | Result | Non-conforming content |

|---|---|---|---|

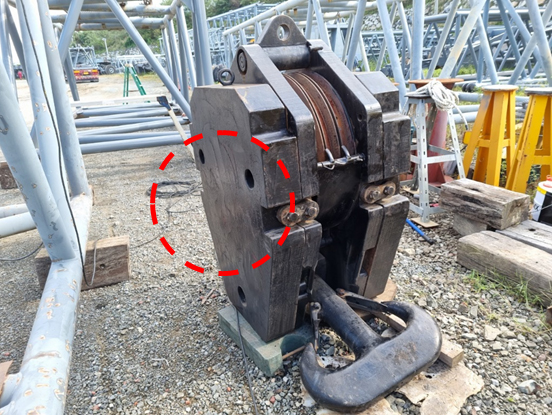

| 1) Brake |

|

O | |

| 2) Track driving device |

|

O | |

| 3) Hook block |

|

O | |

| 4) Wire rope or chain |

|

O | |

| 5) Drum |

|

O | |

| 6) Sheave |

|

||

| 7) Engine |

|

O | |

| 8) Safety device |

|

O |

| Inspection item | Driving device (infinite track) |

|---|---|

| Inspection content | Make sure it matches the manual |

| Pictures of inspection |  |

| Requests for action | Conformity |

| Inspection item | Driving device (infinite track) |

|---|---|

| Inspection content | Verification of the external appearance and operation of drive part, and upper & lower part rollers |

| Pictures of inspection |  |

| Requests for action | Conformity |

| Inspection item | Turntable |

|---|---|

| Inspection content | Verification of bolt (external shaft) connection of turntable |

| Pictures of inspection |  |

| Requests for action | Conformity |

| Inspection item | Wire rope (main) |

|---|---|

| Inspection content | Verification of the external appearance and diameter of wire rope |

| Pictures of inspection |  |

| Requests for action | Conformity |

| Inspection item | Wire rope (boom luffing) |

|---|---|

| Inspection content | Verification of the external appearance and diameter of wire rope |

| Pictures of inspection |  |

| Requests for action | Conformity |

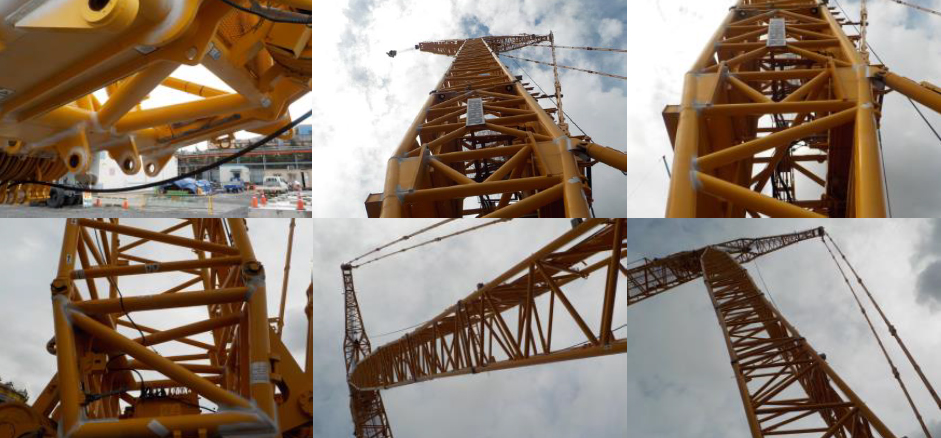

| Inspection item | Inspection of the external appearance of boom |

|---|---|

| Inspection content | Verification of external structure transformation * No performance of the inspection in the way of going down boom due to field conditions |

| Pictures of inspection |  |

| Requests for action | Conformity |

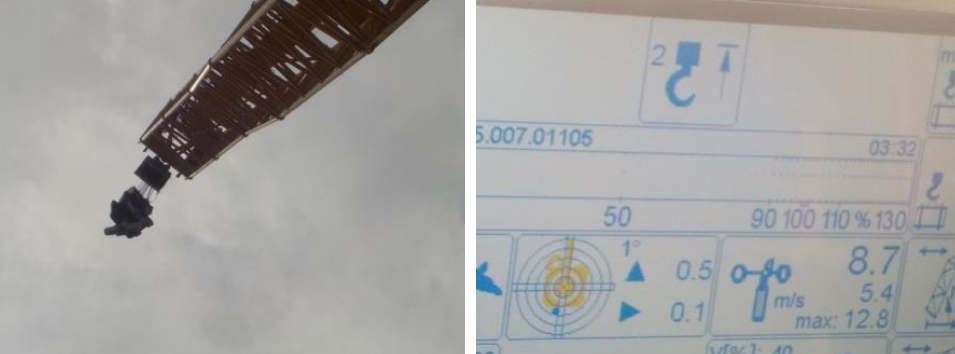

| Inspection item | Luffing boom end |

|---|---|

| Inspection content | Verification of sheave operation and external structure |

| Pictures of inspection |  |

| Requests for action | Conformity |

| Inspection item | Hook block |

|---|---|

| Inspection content | Verification of external appearance, the number of wire rope strands (nine), and wedge |

| Pictures of inspection |  |

| Requests for action | Conformity |

| Inspection item | Over-winding protector |

|---|---|

| Inspection content | Verification of the operation of over-winding protector |

| Pictures of inspection |  |

| Requests for action | Conformity |

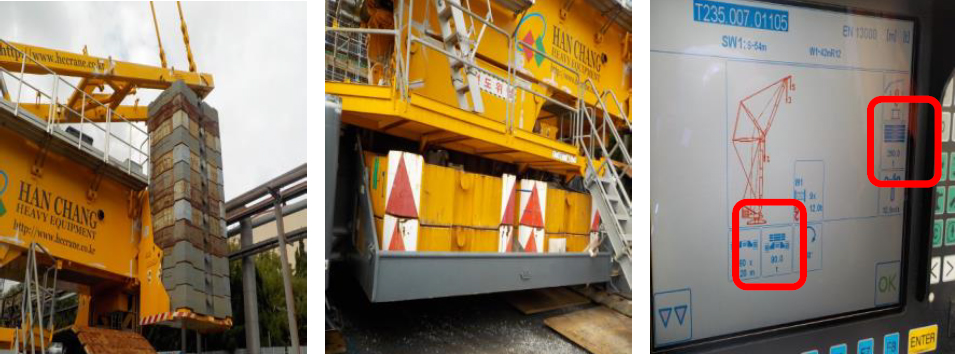

| Inspection item | Crane setting state |

|---|---|

| Inspection content | Counterweight: 250Ton, Carbodyweight: 90Ton |

| Pictures of inspection |  |

| Requests for action | Conformity |

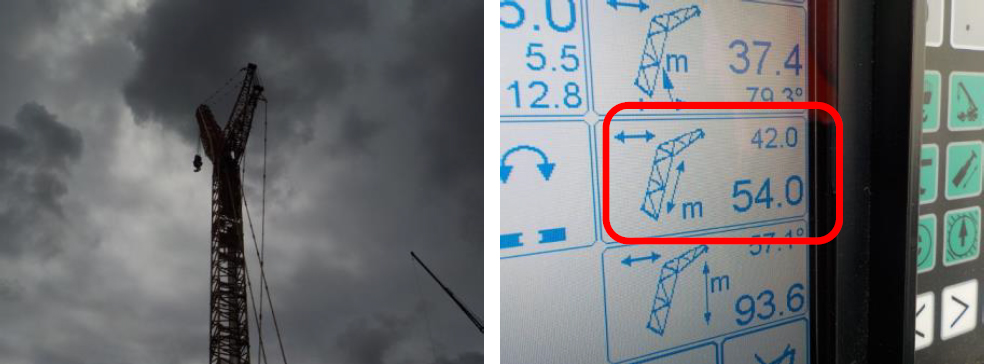

| Inspection item | Crane setting state |

|---|---|

| Inspection content | Main Boom: 54m, Luffing Boom: 42m |

| Pictures of inspection |  |

| Requests for action | Conformity |

| Inspection item | Operation device and three-color-lamp at operation room |

|---|---|

| Inspection content | Verification of the operation of various levers and three-color lamp |

| Pictures of inspection |  |

| Requests for action | Conformity |

| Checkpoint | MAIN BODY |

|

|---|---|---|

| Type | No conformity | Action / Verification |

| Photo |  |

|

| Content | Failure of the upper system (overload) warning lamp at operation room | Verification of the normal operation of overload warning lamp, etc. |

| Checkpoint | TRACK |

|

|---|---|---|

| Type | No conformity | Action / Verification |

| Photo |  |

|

| Content | Loosening arises due to the tension of infinite track. | After tension joint work is done, shoe plate is levelled completely. |

| Checkpoint | BOOM |

|

|---|---|---|

| Type | No conformity | Action / Verification |

| Photo |  |

|

| Content | Rust removal is requested due to boom paint peeling. | After the surface is treated, overall corrosion-resistant coating work is complete. |

| Checkpoint | HOOK |

|

|---|---|---|

| Type | No conformity | Action / Verification |

| Photo |  |

|

| Content | No description of the rated capacity of hook block | After the paint coating work is complete, the rated capacity is displayed. |

Verification of consistency for the structure main body, registration certificate, and machine number

Supply conditions after actions are completely taken for nonconforming cases found in the inspection before carry-in

Inspection is requested to be undertaken in accordance with the inspection standards of Ministry of Labor and Employment

TBM is requested to be made for harmful and dangerous factors before work.

A signaller’s signals are requested to be followed strictly before work.

Removal of risk factors in compliance with the safety management rules for workers

Safety device (over-winding protector, overload protector, luffing limiter, etc.)

Winding devices (wire rope, abrasion, hook sheave, sheave bearing & pin, etc.)

Control devices (brake, lining, lever, pedal, handle, etc.)

Inspection of oil leakage of hydraulic system line (inspection of driving devices like the main body and track)

The operation state of electric devices, and the painting state of external appearance (crack and corrosion resistance of boom, hook, pin, etc.)

The protectors (overload protector, over-winding protector, limit switch, emergency stop device, etc.) attached to construction equipment always have the risk of disasters that may be caused by changes in use conditions, transformation, and careless use. They are required to be inspected primarily before work start regardless of a safety inspection cycle.

Crane specifications depend on a gross weight and boom length. It is required to describe them in a work plan and to compare them with actual crane set values. For work, it is also required to compare the operating radius in the plan with an actual operating radius.

Verification of the consistency between preliminary inspection equipment and the supplied equipment

The disassembled parts, which are not inspected in preliminary inspection, are put together first and then are inspected for safety.

- The operation state, etc. of overload protector, over-winding protector, safety device, and electric device

Action results written in a related form are required to be submitted three days before equipment supply.